A small repair was made to the motion works post, because the tip had broken off at the end where the taper pin slips through. This was done with a simple half-lap joint (hand cut with files), and soldered in place.

The hammer arbour cock was fabricated with brass sheet, and the pieces were hard soldered with silver solder. The process makes for a very scary looking mess, but once everything is cleaned up, filed, and polished, it looks and works beautifully.

The hammer arbour itself is simply a stem with a pivot shaped on each end. The arbour carries a hammer stem, a lifting piece, and a stop pin for the spring.

The lifting piece was cut from 1/16" steel, sanded, polished, and drilled to fit the arbour stem.

The hammer stem was cut from 1/8" thick mild steel bar stock (available at any hardware store). The basic shape was cut out, and the stem portion was rounded and shaped. I will cover my process for rounding the stem in the next post showing the fabrication of the bell stand.

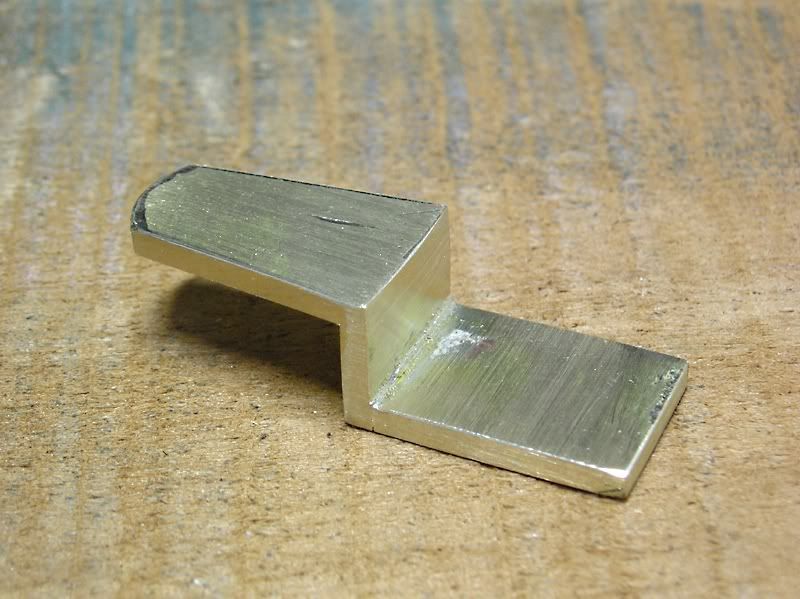

The mounting bolts were a bit fun to fabricate, but ultimately, because I changed the design of the seatboard, they will be useless. I will need to re-make longer ones. The bolts are made from 1/4" mild steel rod, ground/filed slightly thinner at the threaded tips. They are then threaded to fit the pillars (the pillars had to be re-tapped to fit a modern threading), and then square brass tips were fitted and silver soldered to the ends.

Unfortunately, I don't have all my photos in order, so I don't have all the detailed secondary photos of parts like the hammer head, and the hammer stop piece, etc. Stay tuned for the next installment of this ongoing project.

No comments:

Post a Comment